Ideas and discoveries

National centre of competence for industrial 3D printing of polymer materials. CEITEC scientists to contribute their know-how

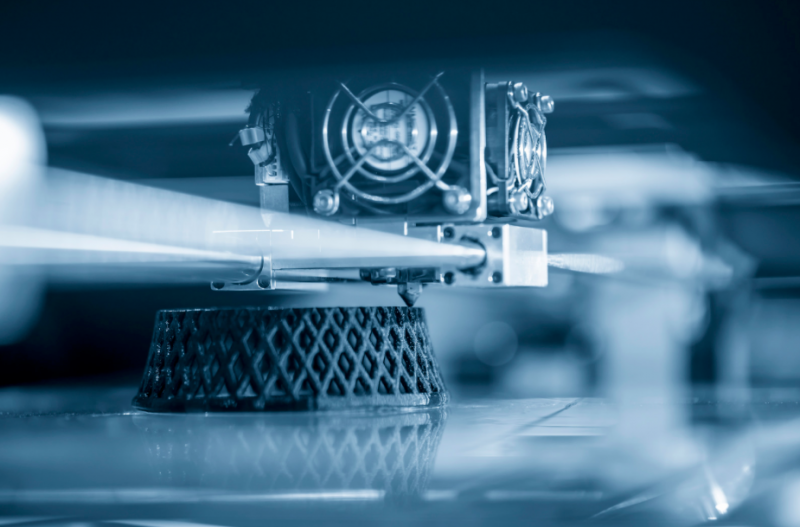

The National Centre of Competence for Industrial 3D Printing of Polymeric Materials (NCC), with an emphasis on supporting environmentally and energetically efficient production, will be established at the Technical University of Liberec. Applied research will focus on more environmentally friendly 3D printing. The aim is to reduce the synthetic component and utilise waste materials, giving them a second life in the production process.

Four departments of the Technical University of Liberec have jointly received support to create the NCC. They are the Institute for Nanomaterials, Advanced Technologies and Innovations of TUL, as well as the faculties of Mechanical Engineering, Textile Engineering, and Mechatronics, Informatics, and Interdisciplinary Studies together with their partners. Starting from January 2023, the centre in Liberec will focus on the efficient use of resources, their recycling, and the utilization of waste natural and synthetic materials in production. The Technical University of Liberec, along with its partners, will establish a strong research programme in the proposed centre for the purposeful ecological use of resources and energy, as well as enhancing the contribution of additive technologies to the industry.

“I believe that, thanks to the centre, we will be able to make significant progress not only in 3D printing itself but also in the field of sustainable materials and digitised production, where we will use resources and energy efficiently. This is how we see the effective connection of research organisations with industry in solving specific problems," Jiří Šafka, the head of NCC for industrial 3D printing, explains.

The research will cover a range of interdisciplinary topics related to environmentally and energetically efficient production. The goal is to increase the potential of additive technologies, enable the development of materials with specific properties as well as new products and innovate technologies, and leverage the potential of digitisation. The concept of the centre is in line with the goals of the Green Deal and the circular economy, emphasising a cradle-to-cradle approach (raw materials circulate in an endless production cycle), efficient use of raw materials and their recycling, as well as the use of waste natural and synthetic materials.

Researchers will strive to reduce the synthetic component in 3D printing by adding natural additives. "We will give a second life to secondary raw materials. By mixing a natural filler with a synthetic one, we will create a new material. We already have results in this direction, such as using sugarcane cuttings. We will also use new materials, which will come from specific manufacturers. Our research will produce real results," Jiří Šafka adds.

Waste from 3D printers will not end up in incinerators

The research will also focus on recycling waste materials from 3D printers. It will not end up in incinerators but can be repurposed for uses like injecting plastics during component production in the automotive industry.

The six-year project was supported by the Technology Agency of the Czech Republic with a grant of more than CZK 280 million. Twenty-six major research organisations and industrial companies from the Czech Republic are involved in the project. For example, ŠKODA AUTO, Entry Engineering, Prusa Development and Prusa Polymers, Siemens, ORLEN UniCRE, ARIES, Brno University of Technology, University of Chemistry and Technology in Prague and Czech Technical University in Prague.

CEITEC BUT is a significant part of the NCC, bringing expertise from a decade of excellent basic material research to applied results. "Our long-standing know-how in materials and 3D printing has great potential to significantly contribute to the development and applications of 3D printing in industrial companies and contribute significantly to their competitiveness," Martin Pumera, a board member of the NCC and head of the Future Energy and Innovation research group at CEITEC BUT says. "The collaboration between research and manufacturing partners of this NCC consortium is a prerequisite for the practical transformation of our fundamental knowledge of natural materials into products with uniquely unattainable parameters using other technologies," Josef Jančář, who leads the advanced polymer materials research group at CEITEC BUT, adds.

Interdisciplinary collaboration between research organisations and industry leaders will allow the sharing of know-how and a multiplicative effect. This will contribute to the long-term and sustainable development of additive technologies in the Czech Republic and thus enhance its competitiveness.

Professor Karel Maca revealed how his sporting spirit is reflected in the leadership of the research team

Women from BUT who move the world of science and technology

Researcher Jakub Lázňovský is developing software for objective evaluation of vertebral fusion success

Researchers are discovering the hidden possibilities of industry and setting a new direction in biology. In the brand new CT laboratory

PROFiBONE: A groundbreaking material for biomedicine is being developed. It can be used to 3D-print bone replacements