Ideas and discoveries

Researchers are discovering the hidden possibilities of industry and setting a new direction in biology. In the brand new CT laboratory

To find out the elemental composition of meteorites, to look into the “guts” of industrial products non-invasively, or to examine biological samples – like human bones from archaeological finds. All this and much more is done by researchers in the Advanced Instrumentation and Methods for Materials Characterization group at CEITEC (Central European Institute of Technology) BUT (Brno University of Technology). Professor Jozef Kaiser leads a team that has become a globally recognized group of experts in imaging methods. With an 18-tonne computed tomography scanner, they scan different sized samples in 3D and participate in industrial development. They also managed to establish two growing spin-off companies. Professor Jozef Kaiser answers questions about CT expertise. Dr. Markéta Tesařová shares her biological achievements.

This year you opened a new industrial CT laboratory at CEITEC, so what preceded it?

I have to go a little further back in time to answer the question. Our research group started in two directions. Even before CEITEC was founded, we were involved in laser-induced microplasma spectrometry, a method for determining the elemental composition of materials. Then we moved on to non-destructive imaging methods, or computed tomography (CT), and we established cooperation with Synchrotron Elettra in Trieste, Italy, which has been a project partner of CEITEC since the beginning. Later, when CEITEC was being established, we decided to build a complementary laboratory with an overlap into industry. We selected instruments on purpose which we could deploy for industrial collaboration, even though CEITEC was still in its infancy as a basic research project. We sensed its growth potential, and so we purchased the instrument, which was placed at the Faculty of Mechanical Engineering of the BUT, because the research centre buildings, in which we are situated now, were not standing here then. At the beginning of this year, due to the reconstruction of the faculty, we had to move the 18-tonne machine to CEITEC after eight years and in May we inaugurated the CT laboratory.

That must have been a difficult move.

Yes, even then it was difficult to get such a heavy device into the faculty. We had to reinforce the floor and move the unit with a crane. The installation of CT was the first major investment of the starting CEITEC. During the move this year, we first had to dismantle half of the building, the shell and use the crane to move it again. But because of this, we have everything under one roof and we don't have to move. We currently have three differently sized CT scanners to cover a wide range of samples, both scientific and industrial. The 18-tonne one for 18 million crowns is the biggest. Today, after our modifications, it would cost almost twice as much.

Did you have the funds for such a large investment or did you have to take out loans?

Thanks to the fact that we have industrial cooperation, we had. I can't remember now how much it cost us, not even in orders of magnitude, but it certainly wasn't cheap.

What do you do in the CT laboratory?

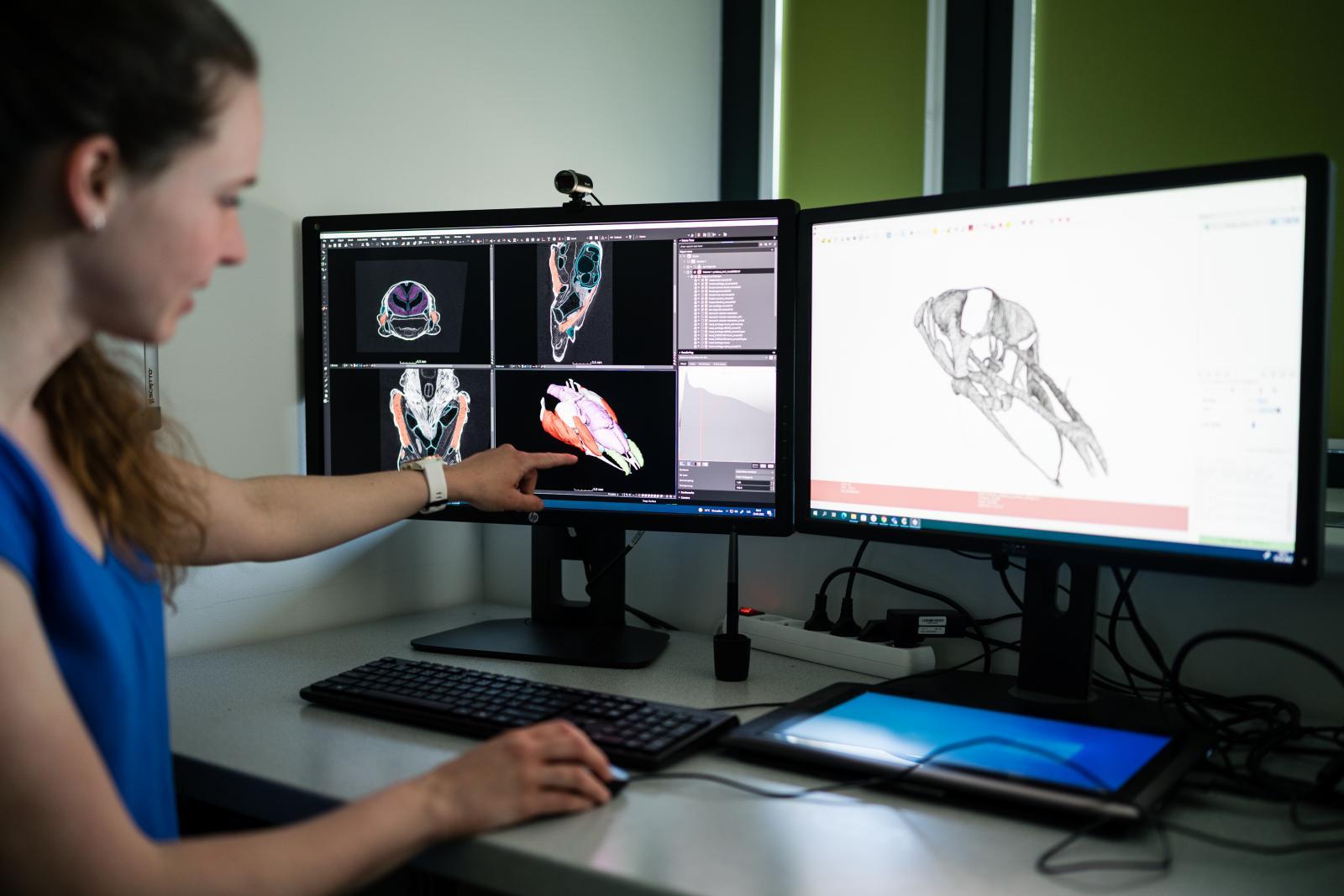

We have basic and applied research in collaboration with industry. Within the basic we deal, among other things, with so-called reverse engineering, where professional programs for display and analysis of data, which are primarily specified for mechanical engineering, are used in biology. And we are very successful. Markéta Tesařová, the project's principal investigator, can tell us more about this.

The biological projects started between 2014–2015 when a group of biologists from Sweden approached us about doing 3D imaging of biological samples. But until then, the laboratory had only dealt with industry and biological objects were not so easy to depict. Data processing was also complicated. As an undergraduate student, I wanted to see if I could do it. I manually created 3D models, which consisted of tracing the structures of interest on about 2000 slides. So it was a kind of student's ant work, but it paid off. For biologists, it was something they hadn't seen before.

Could you give us an example?

We had mouse embryos, for example. Traditionally, they are visualized by other methods – focal microscopy, optical tomography, but their limitation is that the sample size must be small. Whereas we can display samples as large as one meter. We were able to capture and, more importantly, visualize growth in the mouse embryo, covering all developmental stages. From the embryo, we moved on to cartilage, organs, and then the interest moved on to other organisms. Now, for example, we've been studying the regenerative abilities of salamanders. We then supply the collaborating biologists with data that they would not get anywhere else. Without exaggeration, we have thus begun to build a new direction in biology.

What do they use the data for? Why are they important for them?

The biologists we work with do mostly basic research. For example, they were interested in why various genetic developmental diseases arise. Of course, the experiments are not done on humans, the model organism is mice. For example, they wanted to know how a mouse's cartilaginous skull grows. Thanks to our 3D imaging method and the data obtained, they found that during the developmental stages the shape of the skull does not change, only the size. And thanks to this finding, they can explain the biological process. Simply said, they can understand and describe previously unexplained biological mechanisms thanks to data.

Sounds like a major discovery.

We didn't know how crucial this was until we wrote up our findings about mouse embryos and sent them for publication. The article always goes through a review process, during which the reviewers give feedback. But they threw the article away, saying they didn't believe we could image cartilage with CT. At that time we realized that this was a truly revolutionary discovery in biology. This happened in 2017, during that time we have built up quite a name for ourselves, our imaging method has become prestigious and we have been approached by other research groups for collaboration.

I'm really enjoying the biology. In one year, we had two articles in Nature Communications. So the effort we put in is coming back in the form of high-impact articles. But the journey was not easy. The view of biologists and engineers is completely different and it took time to get used to it.

What other research do you plan to do in relation to biology?

I have now submitted a grant application to the prestigious Marie Skłodowska-Curie Actions (MSCA) in collaboration with an institution in Slovenia. We want to take inspiration from biology and apply biological structures to the construction industry. For example, we want to find out what effect facades built on this principle could have on the climate effect.

Let's go back to the cooperation with industry. What is it about?

We have been building this from the beginning and we are aiming for CT expertise, not just CT analysis. We are an application laboratory of Rigaku (Japan) and Thermo Fisher Scientific (USA) and a testing laboratory of Waygate Technologies (formerly GE Inspection Technologies, Germany). We are now working with Thermo Fisher on correlative microscopy, among other things, and I'm excited about that too, because we are already submitting our second grant with them. So we are making our mark on the global scene and on industrial cooperation. In addition, we handle industrial orders, for example, from fibre-reinforced polymers to large plastic parts, where we explore possible defects. Receiving these applied research assignments helps us keep our facilities at the cutting edge.

Would you say that you work with the best instruments in the country?

In certain aspects, for sure. As part of our collaboration with Rigaku, we get to test the latest software as well as hardware capabilities that the device provides. We have here a two-energy source from Rigaku, which was the first in Europe to be used in our country. From GE we tested their flat panel detectors. Through these collaborations, we can then access and test the latest software modules. We also create our own modules, for example we invent software improvements for Rigaku.

Can you explain more how the CT laboratory specifically helps the industry?

JK: Unfortunately, we have a non-disclosure agreement. So I can't give a specific example.

MT: I'll describe it in general terms as I explain it to my grandmother (laughs). A company produces an expensive parts for a car and suddenly finds out at the checkpoint that it has a problem, and of course they don't want to cut the expensive part. So they send it over, we scan it and make a 3D model. We can non-invasively and non-destructively look inside and measure the dimensions, for example, whether there is a well-drilled hole, whether there is a crack and generally some defect. Within two hours, we can tell the company the reason of the problem. So we save them money and time.

JK: Aside from finding defects, we also work with companies to develop new products.

What are your visions for the CT laboratory? What would you like to be more involved in?

Now we have a big project ahead of us, as colleagues at Waygate have developed a huge CT scanner in Cincinnati that uses a linear accelerator (used in medicine to treat cancer) as its source. There are several major aircraft engine and component companies in Cincinnati that make greater use of additive technologies (3D printing). The result is large metal parts that control. And the only possible control is a CT with a high-energy source that can screen large, heavy parts. We would like to bring this system to the Czech Republic or Europe, the Czech Republic is probably too small for that. Beyond that, we continue to do what we have been doing. We are also trying to combine computed tomography with laser spectroscopy at some level to add value and be able to calibrate samples and tell the elemental composition.

Who needs to know the elemental composition?

Geologists, for example. With the help of the device, we can calculate fairly quickly what percentage of uranium or gold is there. We even studied space samples here, we had a few meteorites. Specifically, the one that fell in 2015 near Žďár nad Sázavou. Speaking of space, I must mention that we are now increasingly opening up to space projects.

How does collaboration on projects come about? Do you read something in the newspaper and say to yourself, our methods could be applied to this, I'll try to contact them, or on the contrary, do you already have such a reputation that companies seek you out?

It's more like they're contacting us now. We have several projects at ESA and NASA, so we are visible at some level. But Elon Musk hasn't called us yet (laughs).

Two spin-off companies – CactuX and Lightigo – have been created from your group's research. Can you say more about them?

Lightigo is involved in LIBS technology, so it manufactures and sells laser spectroscopy equipment worldwide, primarily to research institutions. And CactuX was built on the technology we originally wanted from Waygate. It was a pretty simple, wirelessly controlled XY feed into our setups. We ended up doing it ourselves and selling the technology through Waygate, among others. In addition to that, CactuX now does calibration phantoms and other things.

Why start a spin-off company?

One of the advantages of spin-off companies, in my opinion, is that we can retain highly qualified people who don't really want an academic career. On the contrary, they want to realize themselves in business. Most of the leadership positions in these startups are filled by people who came out of our research group.

How challenging is it to separate commercial activity from academia?

It is not an easy process. At the academy, we do research, development, making new things, but we don't turn it into products anymore. We try to stick to terms like idea, realization, prototype. And once it goes beyond the prototype, it has to be done by a spin-off company. As a university, we do not and cannot sell products. The spin-off company does global market research, creates a prototype product, tests it and certifies it.

How do you, as founders, and CEITEC figure in the spin-off company?

In the beginning, we are there in the role of mentor and initial investor. Then we move out of it and we don't interfere with operations anymore. For example, we deal with strategic issues and visions of where to move. CEITEC has licensed several products, so it naturally profits from these companies. Moreover, it continues to cooperate with them, so it is profitable from this point of view as well.

Author: Mgr. Kristýna Filová

CEITEC scientist creates 3D model of a rare cave-dwelling salamander to facilitate its research

The Availability of Resources in the US Gives Me Scientific Freedom, Says CEITEC BUT Graduate

Motor failures in electric vehicles can be detected by mathematical algorithms from the BUT

The memory of Josef Dadok lives on at CEITEC through cutting-edge research in spectroscopy

Awarded student Jiří Kabát uses an electron microscope to measure the temperature of nanoparticles