Topic

9 February 2026

How to give plastics a second (and third) life: Research at FCH VUT may change sorting and recycling

Plastics are an integral part of our everyday lives, but they also represent one of the greatest environmental challenges of our time. Although we sort them, a large part of plastic waste ends up in incinerators or landfills. Research at the Faculty of Chemistry at Brno University of Technology and the project Polymer Marking System for a Digitized Waste Sorting System are responding to this problem. The aim is to make plastic sorting more efficient, increase the quality of recycled material, and give plastics a second life. The project is part of the National Competence Center for Polymer Materials and Technologies for the 21st Century and connects the academic sphere with industrial partners, including associations and clusters.

Why plastic recycling is more complicated than it seems

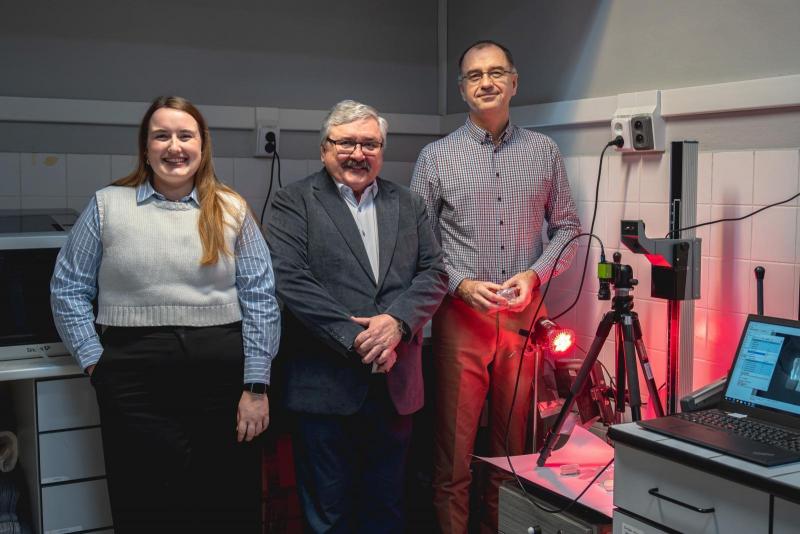

Unlike glass or metals, plastics cannot be recycled indefinitely. With each additional processing cycle, their properties deteriorate – polymer chains shorten, the material becomes more brittle, and its strength and chemical stability change. After several cycles, plastic can no longer be used for the same purpose and must either be downcycled or completely discarded. “The recycling cycle of plastics is far more complex than most people realise. It is important to know how many times a plastic has already been recycled and what it can still be used for,” says Associate Professor Petr Dzik from the Laboratory of Photochemistry, which has been working on this topic for a long time.

“Today in Europe, 42% of polymer waste ends up in energy recovery, 35% in landfills, and only 23% is recycled. There is therefore considerable room for improvement,” adds PhD student Denisa Filipi, who focuses on this issue in her doctoral research under the supervision of Professor Michal Veselý.

Another problem is that plastics ending up in the yellow recycling bin are often a mixture of different polymers. For recycling to be effective, the input material must be as pure as possible – separated, for example, into polyethylene, polypropylene, or polyester. “One of the main challenges of current plastic recycling is not a lack of willingness to sort, but the fact that we often cannot distinguish materials precisely enough. If different polymers get into the recyclate, its quality drops significantly,” explains Professor Veselý.

The solution that researchers from the Faculty of Chemistry at Brno University of Technology (FCH BUT) are developing together with partners is surprisingly elegant: marking polymers with invisible tags that can be easily and quickly recognised by machines. These tags are invisible to the human eye and therefore do not change the appearance of products. They can be read using light in the near-infrared region and enable automatic sorting using cameras and machine vision. “The goal of our research is for the plastic itself to carry information about what it is. An invisible tag allows machines to quickly identify the type of polymer and sort it correctly,” summarises Associate Professor Dzik.

Polymer marking as a key to better sorting

Today, plastic waste is often sorted using a combination of manual and automated approaches. Operators on sorting lines first manually remove contaminants and larger items that could complicate automated sorting, after which the material is processed by machines. Modern sorting lines use near-infrared (NIR) spectroscopy and other optical sensors that can recognise different types of plastics. However, this method has its limits – some polymers have very similar spectra, dark and black plastics are practically invisible to NIR, and mixed materials or textiles are difficult to sort.

While current lines use NIR in an attempt to identify polymer types based on their natural properties, the proposed solution uses the same optical technologies in a different way – to read unambiguous information stored directly in the material using fluorescent markers. This expands sorting capabilities, enables more precise material separation, increases the purity of recyclate, and thus its value. “If polymer marking can be linked with modern sorting technologies, it could fundamentally change the way we handle plastics,” the researchers at FCH BUT agree.

In Brno, there are already sorting lines that could be technically prepared for this system. “We are trying to design a system that can be relatively easily integrated into existing equipment simply by extending it – for example by adding additional cameras or filters,” describes Associate Professor Dzik.

Other marking systems also exist, but they often use inorganic materials that require very energy-intensive or even hazardous radiation (such as X-rays or UV). “This brings risks for operators as well as higher costs. Our solution is significantly more advantageous in terms of safety and sustainability,” adds PhD student Filipi.

The project pays special attention to textile waste, especially polyester. Polyester accounts for approximately 70% of all synthetic fibres and is often combined with cotton. Marking polymer fibres could facilitate the sorting of blended textiles, prove the share of recycled material in products, and help address the impacts of so-called fast fashion. “Marking polymer fibres could help not only with their separation, but also with proving their origin – that is, whether the material was made from recyclate,” explains Professor Veselý.

Plastic and textile waste are not two separate worlds, but a single material stream. An example is a shopping bag, which is very often made from PET bottles. It starts as a plastic bottle, goes through mechanical recycling, becomes a textile fibre, and ends up as a bag.

Why this matters to everyone

The aim of the project is its real-world application – from packaging and textiles to other polymer products. For this reason, it is carried out in cooperation with partners from both academia and industry, including associations and cluster organisations. The main coordinator is the Centre of Organic Chemistry. Academic partners, in addition to FCH BUT, include the University of Chemistry and Technology in Prague and Tomas Bata University in Zlín. Industrial partners include Inotex, ZODPA, Simple Engineering, and Fortemix produkce. Associations involved include NANOPROGRESS, the Czech Chemical Industry Association, and the Plastics Cluster.

FCH BUT focuses on the application of fluorescent markers into polymers, their testing and evaluation, while industrial partners supply top-quality molecules and confirm that the technology is ready for practical use. “A major motivation for us is that research results should not end up in a drawer. We do not want to just publish papers; we are looking for real applications and a path into practice. Seeing laboratory research transform into something that has a real impact is essential for us,” summarises Professor Veselý.

The project also has a strong educational dimension – PhD students are involved in the research, gaining experience with applied research and establishing direct contacts with companies that they can later benefit from on the job market.

The path to a circular economy

More precise sorting has significant environmental impacts – less waste in landfills, more efficient use of raw materials, a lower carbon footprint, and ultimately cost savings. Recycled plastic is today paradoxically often more expensive than virgin material. However, if its quality and yield can be increased, this may change.

Chemical research plays a crucial role. “Chemistry is often perceived as part of the problem, but in reality it is a key part of the solution. Without knowledge of polymers and their behaviour, we would not have any meaningful recycling,” conclude the researchers at FCH BUT.

The proposed innovations may not represent a revolution, but rather a smart improvement of what already exists. The future of recycling may therefore not begin in containers, but at the molecular level – in the structure of the material itself.

-jo-

Source: FCH BUT

Cheaper, better quality and eco-friendly. FCH BUT researchers create new dextrin adhesive

What do science and juggling have in common? Both require patience, says Vojtěch Jašek, who focuses on research in chemical recycling

Ecodesign as a path to sustainability: Researchers from FCH BUT help Czech companies prepare for the future

Nilmore's circular clothing allows you to use the fibre repeatedly

Stevan Gavranović studies environmentally friendly lead-free halide perovskites